All You Need To Know About Power Inverter – Beginner’s Guide

Power Inverter Discussion Points:

1. Introduction

2. Off-Grid and Grid Tie Inverters

3. Pure Sine Wave & Modified Sine wave Inverters

4. Low frequency & High-Frequency Inverters

5. MPPT & PWM Charge Inverters

6. Efficiency of Power Inverters

Recently, as solar PV systems have come to the fore, there is a great interest in inverters today than there ever was. In almost all PV systems, it is the central component that binds the whole system together. Therefore, having the high reliability of an inverter is paramount, as it is the component that is most likely to fail other than the batteries.

The functionality of an inverter is much higher today than it was 10 years ago. The main function of a Power Inverter is to convert DC current into AC current. Inverters come in all shapes and sizes. They are classified mainly on the power rating or the throughput. For example, there are small inverters available that can convert the output from a car battery to run an AC appliance. On the other hand, there are large inverters that convert the output from a whole solar farm. For domestic consumers, Inverters are available with power ratings of 500 to 10,000 watts or 10 kilowatts.

Similarly, inverters are also classified based on the input that they accept. That is, they can accept 12 volt DC, 24 volt DC, 48 or even 96 Volt DC. Note that 48 volt DC input is the most common type of inverter used for residential solar PV systems. While 12 volt DC input inverters are more commonly used in portable applications. Power inverters in a solar farm can also have input voltages from 300 watt DC to 450 volts DC.

Off-Grid and On-Grid Power Inverter

Now that we have introduced inverters, let’s have a look at the most common question asks about them. That is what is the difference between an off-grid inverter and an On-grid inverter. Grid-Tied is also known as an On-grid Solar system. An off-grid inverter is a product that works completely isolated from the grid. It has no provision to tap into the grid electricity or feed electricity to the grid.

Now that we have introduced inverters, let’s have a look at the most common question asks about them. That is what is the difference between an off-grid inverter and an On-grid inverter. Grid-Tied is also known as an On-grid Solar system. An off-grid inverter is a product that works completely isolated from the grid. It has no provision to tap into the grid electricity or feed electricity to the grid.

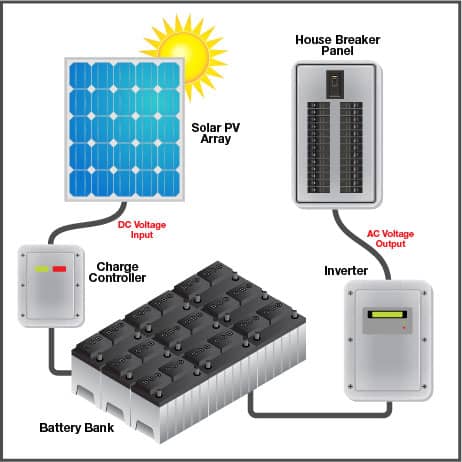

Normally, if a PV system is designed with an off-grid inverter, then the panels are connected with a charge controller. The charge controller is connected to the batteries. The batteries are then connected with an off-grid inverter. Off-grid inverters can also be made for portable use, while grid-tied Inverter cannot. Therefore, inverters that are labeled for use in caravans and motor-homes are off-grid inverters. A grid-tie inverter, on the other hand, can be directly connected to the solar array and the grid. There is also sometimes a charge control option in the grid-tie inverter and therefore some variants can also be connected to the battery pack. In other words, a grid-tie inverter can become the central component of a PV system. The advantage of using a grid-tie inverter is that it can feed excess electricity to the grid and take advantage of net metering. Grid-tie inverters are more expensive because of this additional functionality. Grid-tie inverters can also be used without batteries. Some grid-tie inverters have the added functionality of shutting down the PV system in case of a power outage. This is done to prevent islanding that is grid-tie inverters, ensure that, in the event of a blackout, it will shut down to prevent the energy it transfers from harming any line workers who are sent to fix the power grid.

Advantages of the grid-tie inverter are as follows:

1. Ensures smooth power to the load – That is, it has the ability to top up from either the grid or the battery bank, in case the panels are not producing enough to meet the load.

2. Charge battery from Grid-It can charge the batteries using energy from the grid provided grid charger option is inbuilt. This feature is very useful when the batteries are drained and the panels are not producing enough.

3. Can feed to the Grid-It can feed to the grid when the panels are producing an extra amount of energy.

Let’s have a look at Pure sine-wave & Modified sine-wave inverters.

There are two different kinds of output that a power inverter may furnish. The first one is called a pure sine-wave and the second one is called a modified sine-wave.

The modified sine-wave inverters are much cheaper than pure sine-wave inverters, and that is because they have less circuitry. Modify sine wave inverter use transistors that act as a switch, and they basically turn on and off the current to create a staircase pulse or a square wave. Appliances that use the output from modified sine-wave tend to overuse power and run hotter and thus become a bit inefficient. Pure sine-wave inverters, on the other hand, run electrical appliances, much smoother – appliances run without bus or hiss sound.

Now, let’s have a look at low frequency and high-frequency Inverters.

Inverters can be classified into two categories based on the speed of the operation of transistor switches in the commutator circuit. The categories are, namely low frequency, inverters, and high-frequency inverters.

Inverters can be classified into two categories based on the speed of the operation of transistor switches in the commutator circuit. The categories are, namely low frequency, inverters, and high-frequency inverters.

A low-frequency inverter has several advantages, but it is more expensive and because of the presence of a massive iron core in its transformer, it is also much bigger and heavier compared to its high-frequency counterpart. Often difficult loads that require high surge at the beginning, such as Motors, Compressors, or Pumps are very well managed by Low-frequency Inverter. Field-effect transistors and Low-frequency Inverters can operate cooler in part due to the slower frequency of switching required to produce AC power. In a High-frequency Inverter, there is almost twice the number of components compared to low-frequency inverters. Nonetheless, they are still smaller and lighter overall because of the absence of a large central transformer. They are not very well equipped to handle industrial loads and therefore, if a large pump or motor or an air conditioner is required to be run, then a low-frequency inverter is a better option.

High-frequency inverters application is appropriate for a wide variety of uses, like tools, battery chargers, small appliances, AV, and computers. High-frequency inverters make up the large majority of inverters available in the Retail Market. High-frequency inverters are also available in lower power categories such as 300, 600, 1000, and 1500 watts, etc, as opposed to low-frequency inverters with the power levels normally within 1000s, typically 2000 to 3000 watts.

Now, let’s look at MPPT and PWM charger inverters

A solar inverter is different from a normal inverter, in that it has a charge controller built into it. Therefore, inverters used by solar systems also come with either MPPT or PWM options.

The MPPT functionality allows more power to be drawn out of the solar panels. This is done by keeping the panel’s output close to the maximum power point of the panels. Inverters with MPPT functionality are more expensive than the PWM option. It has been noted experimentally that overall MPPT can make the solar energy system up to 20 percent more efficient.

The PWM option, on the other hand, is a good low-cost solution for small systems only when the solar cell temperature is mortared too high, that is, between 45°C to 75 °C. PWM inverters prefer unshaded irradiance on the panel and tend not to work very efficiently if the panel is shaded.

Now, let’s stretch upon the efficiency of inverters. Losses are expected whenever we are dealing with the energy conversion process. Similarly, when we convert DC electricity to AC electricity, there will be losses. As of July 2009, most grid-tie inverters available on the market, have peak efficiencies of over 94 % and some as high as 96 %. The energy loss during the conversion process is mostly heat, and this concludes the Power Inverter topic.